HDPE Pipes

HDPE Pipes are used in many fields

Irrigation

HDPE pipe for irrigation and water is manufactured for excellent performance and a long life expectancy. Highly resistant to corrosion and weather, recent studies conclude it will last at least 100 years

Water

HDPE manufactured from the Virgin High grade of Polyethylene resins. materials contain choice of polymers and high quality carbon black to get life under every working and weather conditions.

Fire fighting

HDPE pipes and fittings are manufactured as per ISO and AWWA Standards. Products are required to pass strict quality control procedures, and are rigorously monitored throughout the production process.

Gas

Polyethylene Pipes represent the material of choice for most gas distribution applications in North America and throughout the world. For US applications their use is governed by 49 CFR 192 which prescribes the design

Manufacturing Forms

ALROWAD PIPES ARE MANUFACTURED ACCORDING TO DIN 8074/ 8075 , ISO 4427:2007

Alrowad Quality Control

The quality management system in Alrowad company guarantees the quality of the final product using most advance production methods and carrying the quality control tests specified in standards before and during production.

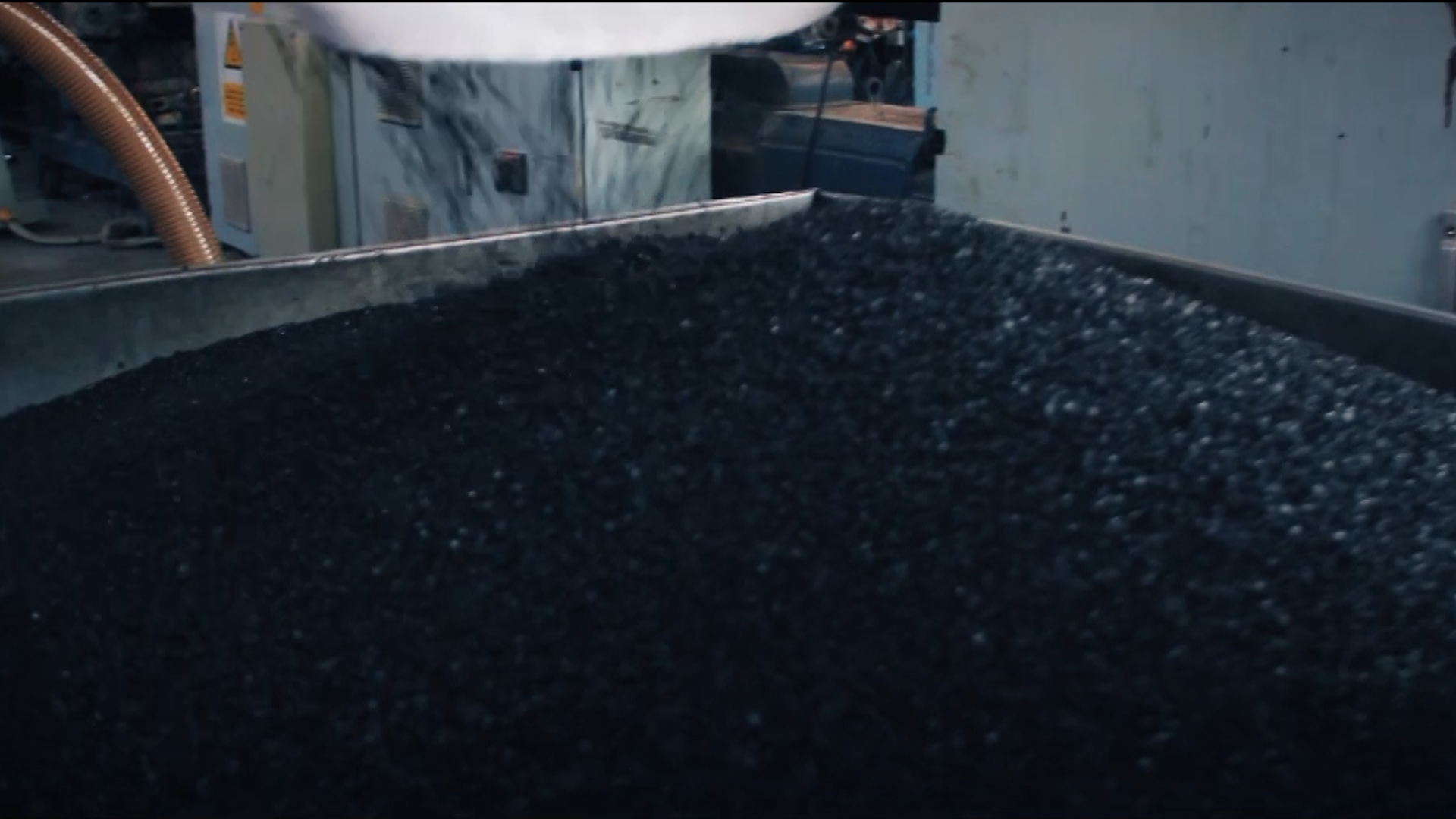

Raw Material

Density Test – Melt Flow Rate

Standards:

PrEn 12202

I&EN IOS 1183

IOS 1133

HDPE Pipes Standards

Relevent Standards- DIN 8074 / 75& / IOS4427:2007. – EN 10S 6259. – EN 921&10S1167 – IOS 2505 – 1 / 2. – EN 638&10S 6259 – 1. – 10S 13479.

HDPE Pipes Types

Tests Type Appearance & Dimension Measurement.

Tensile Strength.

Hydrostatic Pressure Test

Longitudinal Heat Reversion.

– Elongation @ Break

– Slow Crack Growth.

Physical and Mechanical Properties Of The Material

Our HDPE pipes are generally resistant to the chemicals commonly used for water treatment and disinfection. Our HDPE pipes have excellent resistance to naturally occurring chemicals found in the soil for industrial purposes our HDPE 100 pipes have excellent resistance to different media.